Quality Check OK Sticker: A Comprehensive Guide

When it comes to ensuring the quality of products, the use of a quality check OK sticker is a common and effective practice. This small yet powerful sticker serves as a visual indicator that a product has passed a series of quality checks and meets the required standards. In this article, we will delve into the various aspects of the quality check OK sticker, including its purpose, types, benefits, and how to use it effectively.

Purpose of Quality Check OK Sticker

The primary purpose of a quality check OK sticker is to provide a clear and immediate visual confirmation that a product has been inspected and deemed to meet the specified quality criteria. This helps in building trust among consumers, as they can easily identify products that have undergone a thorough quality control process.

Types of Quality Check OK Stickers

There are several types of quality check OK stickers available, each with its own unique design and features. Here are some of the most common types:

-

Standard Quality Check OK Sticker: This is the most common type of sticker, featuring a simple “OK” or “Pass” logo with a background color, typically green or blue.

-

Custom Quality Check OK Sticker: These stickers can be customized with specific information, such as the company logo, product name, or quality standards met.

-

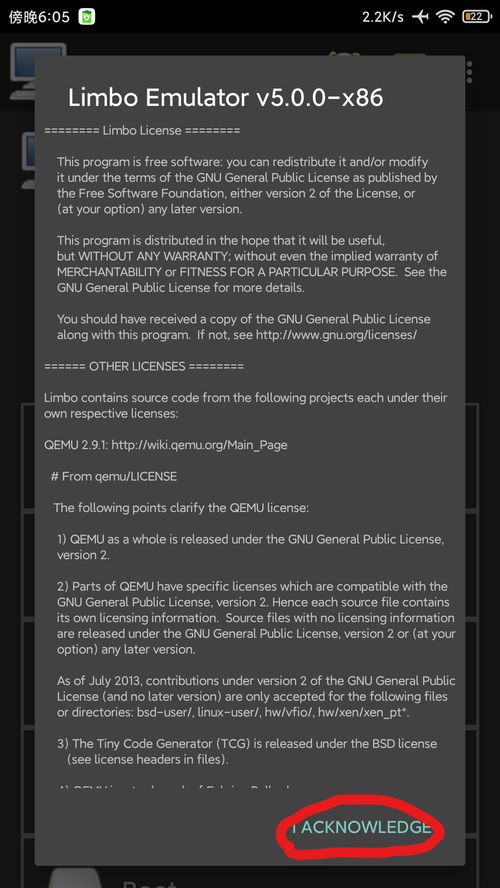

QR Code Quality Check OK Sticker: This type of sticker includes a QR code that, when scanned, provides detailed information about the product’s quality and inspection process.

-

Transparent Quality Check OK Sticker: These stickers are designed to be placed over the product’s packaging, allowing the original packaging to be visible while still indicating the product’s quality status.

Benefits of Using Quality Check OK Stickers

Using quality check OK stickers offers several benefits for both businesses and consumers:

-

Enhanced Consumer Trust: By visibly indicating that a product has passed quality checks, businesses can build trust and credibility among consumers.

-

Increased Productivity: Quality check OK stickers help streamline the quality control process, allowing businesses to identify and address issues more efficiently.

-

Cost Savings: By reducing the number of defective products that reach the market, businesses can save on costs associated with returns, repairs, and replacements.

-

Brand Image Improvement: Consistently high-quality products contribute to a positive brand image, which can lead to increased customer loyalty and market share.

How to Use Quality Check OK Stickers Effectively

Using quality check OK stickers effectively involves several key steps:

-

Establish Clear Quality Standards: Define the specific criteria that a product must meet to be deemed “OK” or “Pass” for quality.

-

Train Quality Inspectors: Ensure that all quality inspectors are properly trained to identify and document any issues that may affect product quality.

-

Implement a Quality Control Process: Develop a systematic approach to inspecting products and applying quality check OK stickers.

-

Monitor and Review: Regularly review the quality control process and make adjustments as needed to maintain consistent product quality.

-

Communicate with Consumers: Clearly communicate the purpose and significance of the quality check OK sticker to consumers, helping them understand the value of the product.

Table: Comparison of Different Quality Check OK Sticker Types

| Type | Description | Benefits | Best Use Cases |

|---|---|---|---|

| Standard Quality Check OK Sticker | Simple “OK” or “Pass” logo with background color | Cost-effective, easy to apply | General product quality indication |

| Custom Quality Check OK Sticker | Customizable with company logo, product name, etc. | Brand promotion, specific product identification |